Project title: Anaerobic Digester Performance and Modelling of Power Generation

Industry partner: Rivalea (Australia) Pty. Ltd. is a leading Australian agri-business supplying approximately 20% of the domestic fresh pork market. The company’s headquarters are located in Corowa, NSW and there are piggery operations in Corowa, Albury, Deniliquin, Bendigo and St Arnaud in western Victoria. Rivalea also has stock feed mills and meat processing facilities in Corowa and Laverton, Melbourne. Rivalea’s operations are energy intensive both in the milling of feed, rearing livestock and meat processing operations. The introduction of the Federal Government carbon abatement programs and large increases in energy prices in recent years has incentivized the company to build out its own energy generation plant using farm and plant resources. Rivalea recognizes that biogas generated in the waste water treatment lagoons is a potential source of energy in the operations of the farm and processing facilities.

Project background:

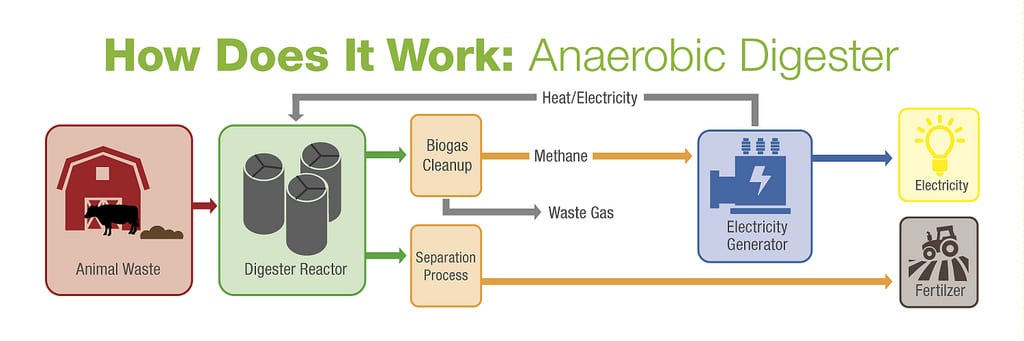

Biogas is about 20% lighter than air and has an ignition temperature range of 650 to 750 degrees celsius. It is also a colourless and odourless gas that produces a clear blue flame when burned similar to natural gas. Biogas can potentially be used in conjunction with many types of equipment for electricity and/or heat production. Current methods include Gas Turbine Engine, Microturbine Engine, Internal Combustion (Piston) Engine, Stirling Heat Engine, Boiler (Steam) Systems, Process Heaters (Furnaces), Combined Heat and Power (CHP) units, and Fuel Cells. All these technologies have the capability to produce electricity from biogas. Fuel cells offer great prospects for small-scale power plant usage, with low emissions and capabilities of producing power and heat with efficiency exceeding 60% as compared to reciprocating engines and turbine engines at 30% and 40% respectively. Internal combustion engines are the most commonly used to produce both heat and power. The internal combustion engines require a very clean fuel; hence the system requires removal of water vapours and H2S (hydrogen sulphide) to below 100ppm. Gas turbines/micro-turbines are comparable to spark ignition engines in terms of efficiency and require minimal maintenance. However, gas turbines can require a high initial investment. There is a gap in knowledge regarding biogas power generation method for a gas turbine. This is due to insufficient calculations available for thermal efficiency. The efficiency varies drastically depending on engine make and model that is used, as well as the relevant modifications made to the commercially available engines. Another complicating factor in the calculation of thermal efficiency is related to the compositional variation between geographical locations.

Project aims:

- Review waste water treatment processes and assess the potential energy created by production of Methane gas and greenhouse gas balance using historical data (2012-2018) such as flow rate, BOD, COD, VFA, pH EC, total solids.

- Compare the organic materials available at the Huntly site and model biogas production using industry models and compare to historical production at Rivalea’s Corowa biogas plant.

- Recommend a system for biogas produced on site at Huntly based on commercially available components where components selected take consideration of site-specific data for the Huntly plant.

- Investigate various power generating technologies and produce comparable life cycle analysis to determine the most cost effective option for the site.

Project deliverables:

| Deliverable | Description | Initial Timing Estimate |

| Project plan | Project Plan- statement of the problem | |

| Milestone 1 | Literature review and best practice, data collection | |

| Milestone 2 | Methodology, collection of data & analysis, data visualization and data processing; including flow rate, BOD, COD, VFA, pH EC, total solids.

· Assess data on biogas production taking account of the Influence of temperature – summer vs winter. · Assess data on feed type, quality and quantity and animal weights and gains to determine the carbon budget of the facility |

|

| Milestone 3 | Draft findings- report back to client and feedback. | |

| Draft project report | Draft project report | |

| Project report | Project report. | |

| Presentation | Final presentation on the project with accompanying presentation materials. |

Students:

- 02 engineering students (environmental/mechanical/sustainable systems/electrical)