Project title: Enhancing Anaerobic Lagoon Performance Industry partner: Rivalea (Australia) Pty. Ltd. is a leading Australian agri-business supplying approximately 20% of the domestic fresh pork market. The company’s headquarters is located in Corowa, NSW and there are piggery operations in Corowa, Albury, Deniliquin, Bendigo and St Arnaud in western Victoria. Rivalea also has stock feed mills and meat processing facilities in Corowa and Laverton, Melbourne. Rivalea’s operations are energy intensive both in the milling of feed, rearing livestock and meat processing operations. The introduction of the Federal Government carbon abatement programs and large increases in energy prices in recent years has incentivized the company to build out its own energy generation plant using farm and plant resources. Rivalea recognizes that biogas generated in the waste water treatment lagoons is a potential source of energy in the operations of the farm and processing facilities. Project aims:

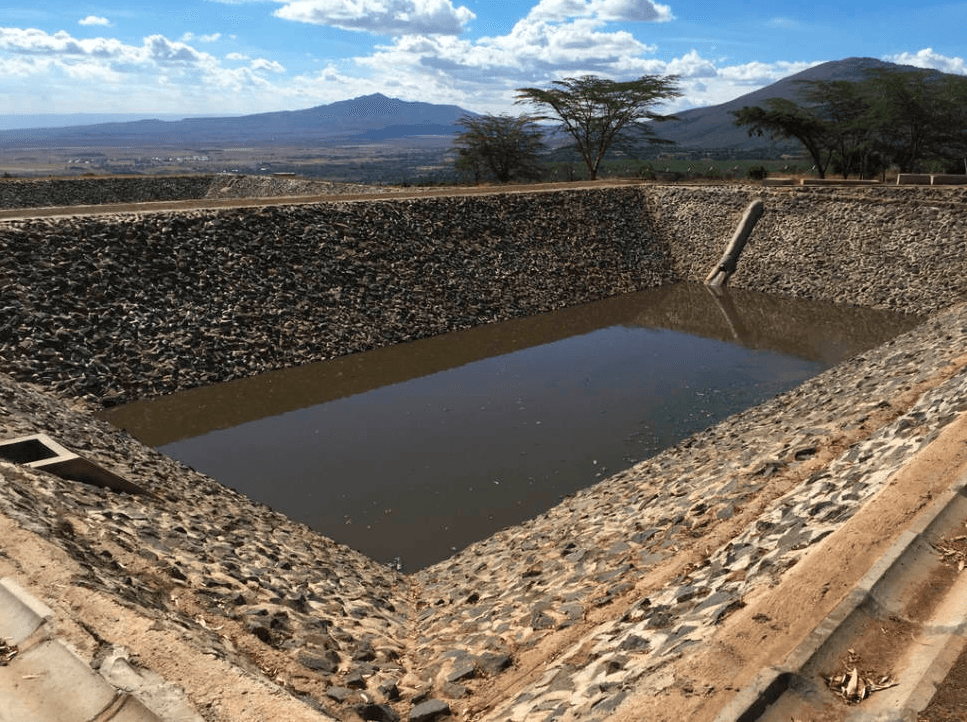

- Examine and study the efficiency and operation of anaerobic lagoons at the Huntly Piggery Site.

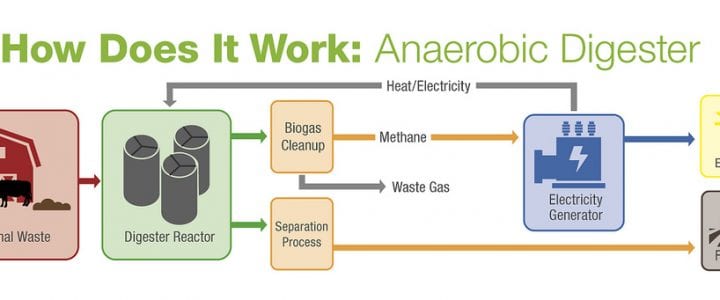

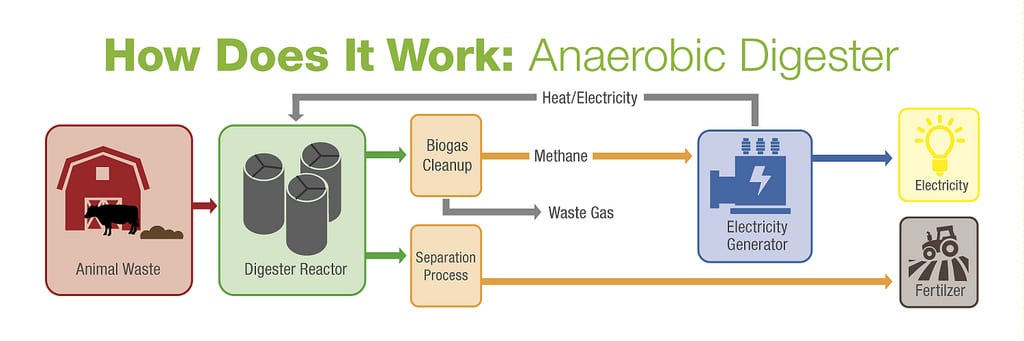

- Characterise waste and mass balances for bio-energy production and energy recovery.

- Analyse lagoon performance using existing data.

- Explore opportunities to enhance lagoon performance, paying attention to mass balance, carbon, nitrogen, sludge management.

- Simulate and model lagoon performance- energy mass balance modelling.

Project deliverable:

| Deliverable | Description | Initial Timing Estimate |

| Project plan | Project Plan and statement of the problem- Performance of Anaerobic lagoons | |

| Milestone 1 | Literature review and best practice for managing pig waste in lagoon systems and mass energy balances | |

| Milestone 2 | Methodology, collection of data & analysis from Rivalea around lagoon performance data-flow rate, BOD, COD, Volatile fatty acids, pH, nutrient balances etc.. Modelling of Lagoons and Mass energy modelling | |

| Milestone 3 | Draft findings- report back to client feedback. | |

| Draft project report | Draft project report | |

| Project report | Project report. | |

| Presentation | Final presentation on the project with accompanying presentation materials. |

STUDENT SELECTION:

- 02 Environmental Engineering/Science students

Attributes required include:

- Ability to read and summarise research papers

- Strong analytical skills

- Logical thinker

- Excellent problem solving skills

- Good communication skills

Skill Set:

- Environmental Engineering

- Microbiology

- Data Analysis Mathematics and Analytics

Image: https://www.flickr.com/photos/marijkemooy/6817902484/

Image: https://www.flickr.com/photos/marijkemooy/6817902484/